TOPICALS

LUDDEN & MENNEKES PROVIDES PERFECTED EQUIPMENT FOR EFFICIENT TRANSPORT.

New transfer station for household waste and bulky waste at the North-Rhine Westphalian Bedburg for a more sustainable transport.

Bedburg. LUDDEN & MENNEKES ENTSORGUNGS-SYSTEME GmbH provides plants for the compaction of residual material and recyclable raw materials as a major contribution to the circular economy and thus for the preservation of natural resources.

The reconstructed transfer station for household waste and bulky waste at the North-Rhine-Westphalian Bedburg-Hau allows the company to provide proven quality and best results in respect to the capacity utilization of the new plant. The reduction in volume of regionally collected waste and recyclable material makes sure that the specialist for compacting equipment can offer efficient transport from the customer to the supra-regional sorting and recycling plants.

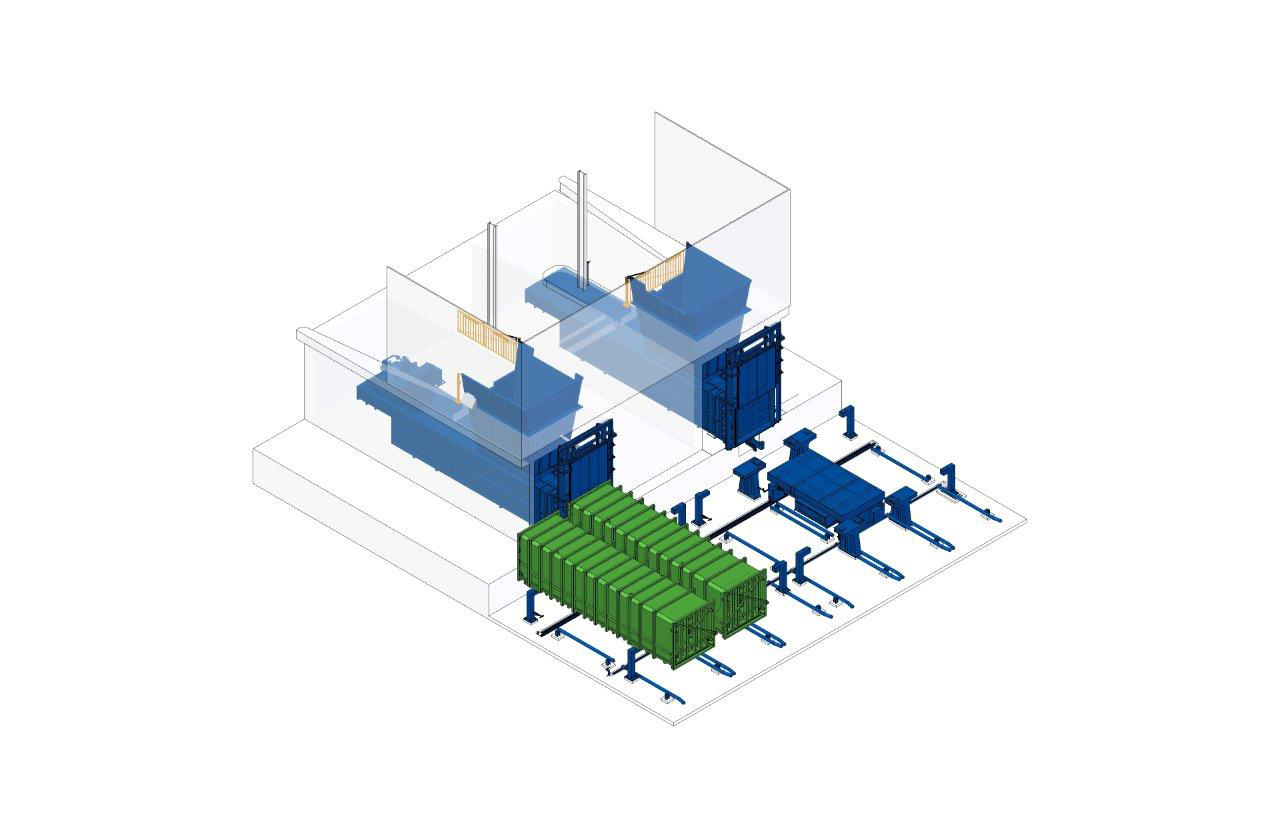

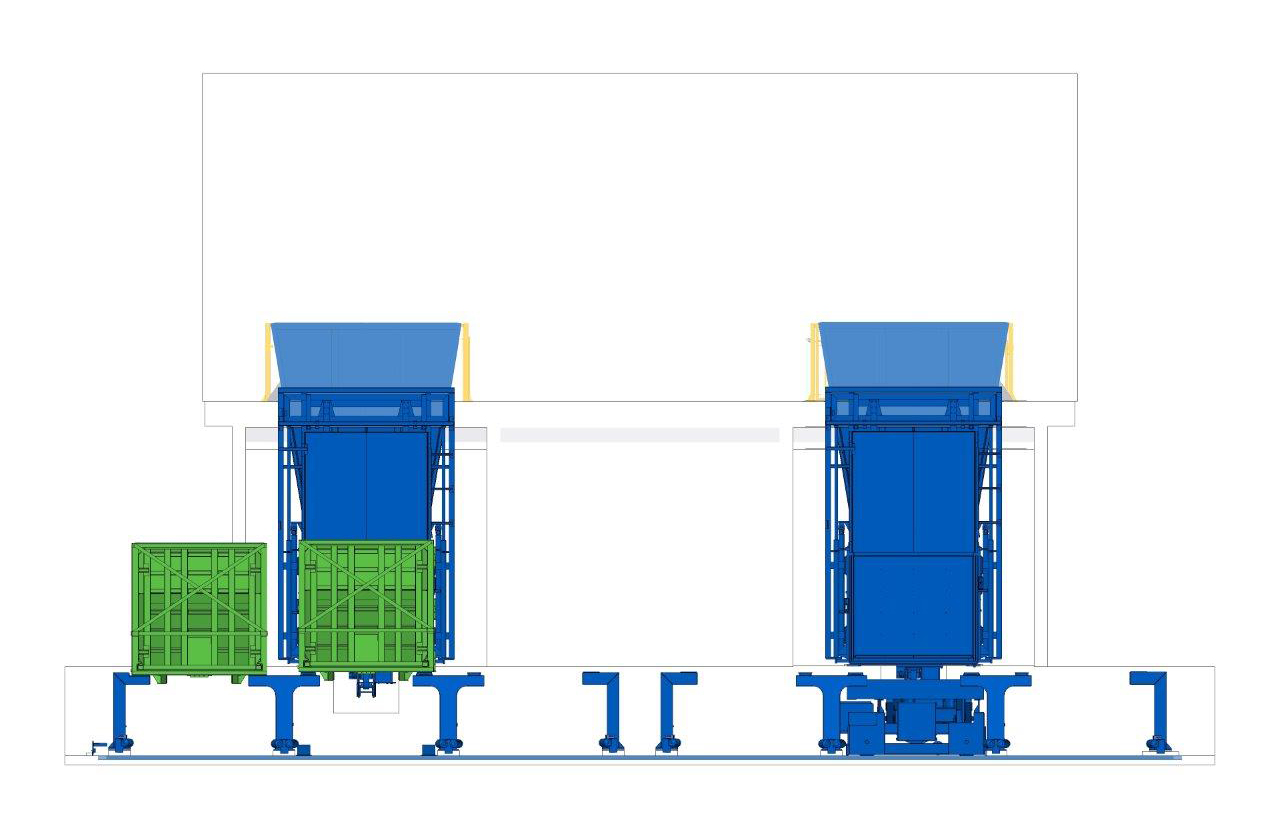

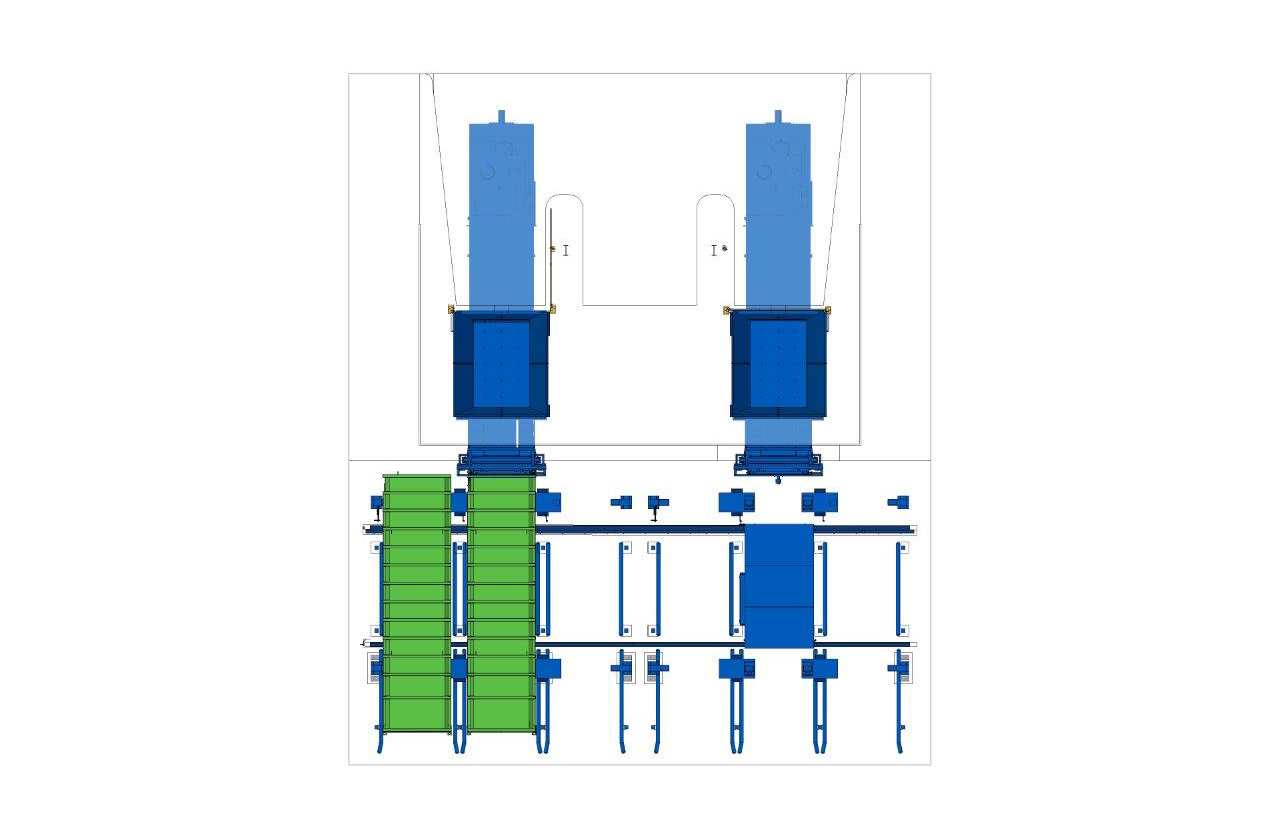

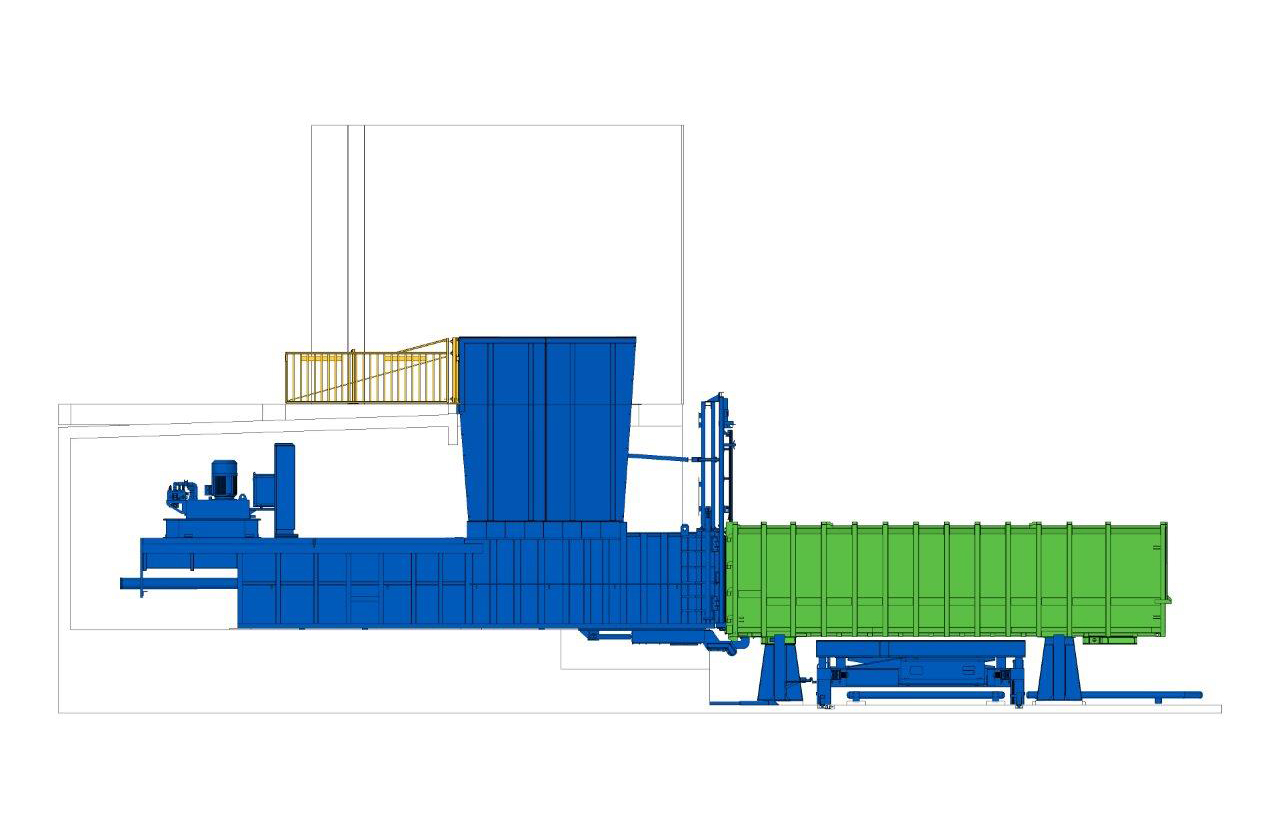

THE PROJECT. In 2017 LUDDEN & MENNEKES GmbH secured an order for the construction/reconstruction of a transfer station for household waste and bulky waste at Bedburg-Hau. From the beginning, the engineering company, which has specialized in environmental technology, designed the Moyland reloading system in close cooperation with the KKA GmbH operator as well as the Schönmackers Umweltdienste GmbH & Co KG disposal company.

The plant consists of two static compactors (STV 10,000), a container station/traversing unit and seven special coupleable containers to compact household waste and bulky waste by pressing forces of up to 1,000 kN at filling weights of 17 to 19 tons (maximum filling weight: 25 tons). Thanks to the good cooperation between the customer and plant manufacturer during the planning and design phase as well as the erection and commissioning of the transfer station, we achieved an optimum result: The admissible total mass of the transport vehicles is completely used, but not exceeded.

In addition, a tailor-made service contract assures the operators that their plants will run efficiently and safely in the years to follow.

LUDDEN & MENNEKES’s customized transfer stations can offer all means which are required for the implementation of an efficient and thus low-cost and resources-preserving transport of the regional collection to a central plant for further processing.

Regarding the scarcity of natural resources, functional waste management cannot be dispensed with. An area within this circular economy is the treatment of residual waste and recyclable raw materials in sorting and recycling systems. Using their perfected equipment, LUDDEN & MENNEKES can significantly contribute to an increase in the production of secondary raw materials.

THE COMPANY.Since 1991 LUDDEN & MENNEKES ENTSORGUNGS-SYSTEME GmbH has implemented powerful plants for an application in the waste disposal industry. Today, the renowned expert in the field of compaction systems and transfer stations employs more than 180 staff members at their two sites in the North German Meppen and Dörpen. The product range of the Lower Saxony-based company comprises the sale and rent of mobile and static compactors, bin tippers as well as special plants and the pertaining components.

In addition to a large number of series products LUDDEN & MENNEKES can design and implement specific plant solutions for individual customer requirements. From the planning and design to the manufacture and installation as well as the after-sales service, LUDDEN & MENNEKES can offer extensive support over the entire project time for the customers.

PRESS CONTACT

Matthias Bolmer

Sales/ Marketing

+49 (0) 59327215 - 8041

matthias.bolmer@ludden.de

LUDDEN & MENNEKES ENTSORGUNGS-SYSTEME GMBH

Essener Straße 13

49716 Meppen - Germany

+49 (0) 5932 / 7215 0

info@ludden.de

www.ludden.de