TOPICALS

Stationary cardboard tube compacting at its best

L&M optimises its screw-type compactor for maximum compacting of cardboard tubes

STATIONARY CARDBOARD TUBE COMPACTING AT ITS BEST

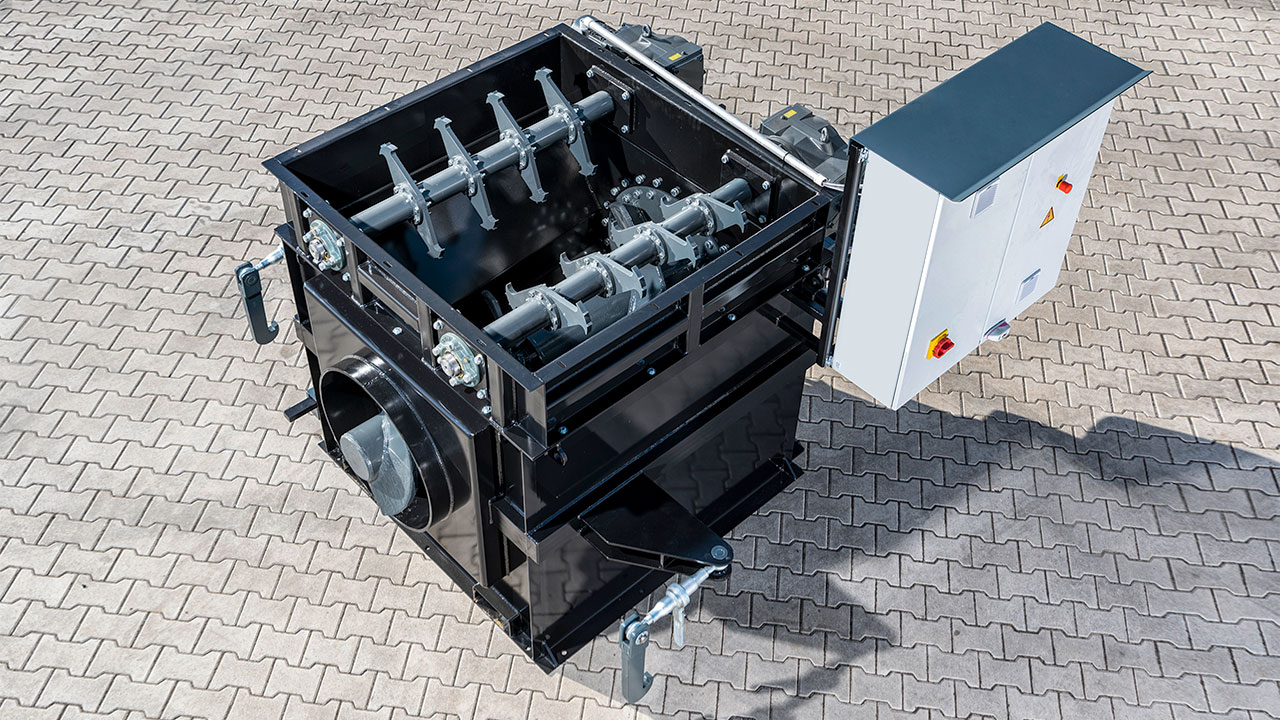

Meppen. Stationary compactor systems of the SVS type series – also known as screw-type compactors – are put to use where larger quantities of residual materials and recyclable raw materials must be extremely highly compacted before transport. The machine manufacturer Ludden & Mennekes Entsorgungs-Systeme GmbH has optimised its existing screw-type compactor especially for shredding cardboard tubes and equipped it, among other things, with a modified screw flight pressing system.

To shred the cardboard tubes in advance, an additional pre-shredder was added in front of the main screw.

The optimised screw-type compactor shreds up to 20 cardboard tubes with a wall thickness of 20 mm and a diameter of up to 400 mm. The L&M screw-type compactor achieves a theoretical overall throughput capacity of 60 to 120 m³ per hour.

Engineers at L&M technically modified the geometry of the screw flight and furnished it with additional steel teeth specifically to process cardboard tubes. These highly wearable steel teeth are cathodic dip coated and bolted, so they can be easily replaced as needed. Even the crushing properties of the SVS have been modified with design changes. With its additional hard surfacing combined with the direct drive, the screw flight achieves a power transmission of 90%.

Customer-specific settings, such as the type of feed, weights or different materials can be adjusted via the touch display. Multiple programmes are available to save these settings.

The option of remote maintenance by trained L&M personnel is available for diagnostics and any possible troubleshooting. This allows maintenance and location-specific adjustments to be carried out flexibly.

The system is optionally available with fully automated container change operation.